PRODUCTION CAPABILITIES AND DIE CASTING MACHINE LIST

It’s all about performance! At Pintejin Group we take pride in our productivity and efficiency in all operations. We purchase brand-new equipment from the best manufacturers in the business so that we always have the latest and most cost efficient technology available.

Each job that we process begins with a “DFM” meeting to determine the best and lowest cost method of producing that particular part or assembly. With Our Die Casting Equipment,Pintejin Die Casting owns an assortment of die casting and related machines that allow us to improve uptime, reduce inventory and increase scheduling flexibility for our customers’ orders. With multiple big-ton casting machines, we provide the most economical solutions for each customer’s.An important factor in those meetings is matching the job to the machines. Of special note is that all of our CNC Machining Centers include custom designed, zero-point quick-change fixtures.. The zero-point fixtures significantly reduce change-over time as well as increase batch to batch consistency.

All of these things add up to processing your parts with the highest level of quality at the lowest possible cost! Following is a brief overview of our capabilities.

DIE CASTING MACHINE WORKSHOP

Pintejin die casting company does more than cast aluminum and zinc alloys. Our value-added secondary die casting services allow us to tailor your cast components to your specifications. We are your one-stop shop for cold/hot chamber die casting — from concept and engineering to full production. Whether you need our assistance with service parts, ongoing production or anything in between, we will handle it. No job is too big or too small for Pintejin Die Casting company!

| TONNAGE | 30T | 280T | 400T | 500T | 800T | 1250T | 1650T | 2000T | 2700T | 3000T |

| SET | 15 | 13 | 3 | 2 | 1 | 1 | 1 | 1 | 1 | 1 |

| EST CAPACITY/ MONTH | 60K | 46K | 43K | 43K | 39K | 31K | 26K | 23K | 21K | 19K |

Cold Chamber Die Casting Machine Workshop

YIZUMI DM 1650t Die Casting Machine

YIZUMI DM 400t Die Casting Machine

SANJI Overhaul 550t Die Casting Machine

lijing 280T die casting machine

3000T LIBI DIE CASTING MACHINE

200 T Hot Chamber Die Casting Machine

30T Zinc Hot Chamber Die Casting Machine

CNC MACHINING MACHINE WORKSHOP

CNC machining capabilities include small part production, second operation parts, as well as short runs and prototyping and our world-class expertise, know-how, and equipment, our metal milling staff can take even the most intricate geometries that your design engineers can envision and help you turn that vision into reality. CNC milling can produce nearly any 2D or 3D shape.

| NAME | 3 AXIS CNC MACHINE | 4 AXIS CNC MACHINE | 5 AXIS CNC MACHINE | PRECISION LATHE | CNC ENGRAVING | 5 AXIS TURN-MILL MACHINE |

| SET | 30 | 18 | 2 | 15 | 3 | 1 |

| EST CAPACITY/ MONTH | 6K | 5K | 2K | 15K | 2K | 1K |

5 Axis CNC Engraving Machine

Mazak 5 Axis Cnc Machine

YIMEI Single Column Cnc Turn-Mill Center

4 Axis Mazak Turn-Mill

DMU50 5-Axis CNC

SY-650 Engraving-Mill

DIE CASTING TOOLING WORKSHOP

The tooling room is also the process equipment room, and various tools used in the manufacturing process, such as tools, fixtures, molds, measuring tools, inspection tools, auxiliary tools, bench tools, station tools, etc.In engineering and manufacturing, toolroom activity is everything related to tool-and-die facilities in contrast to production line activity.

Automatic Surface Grinder

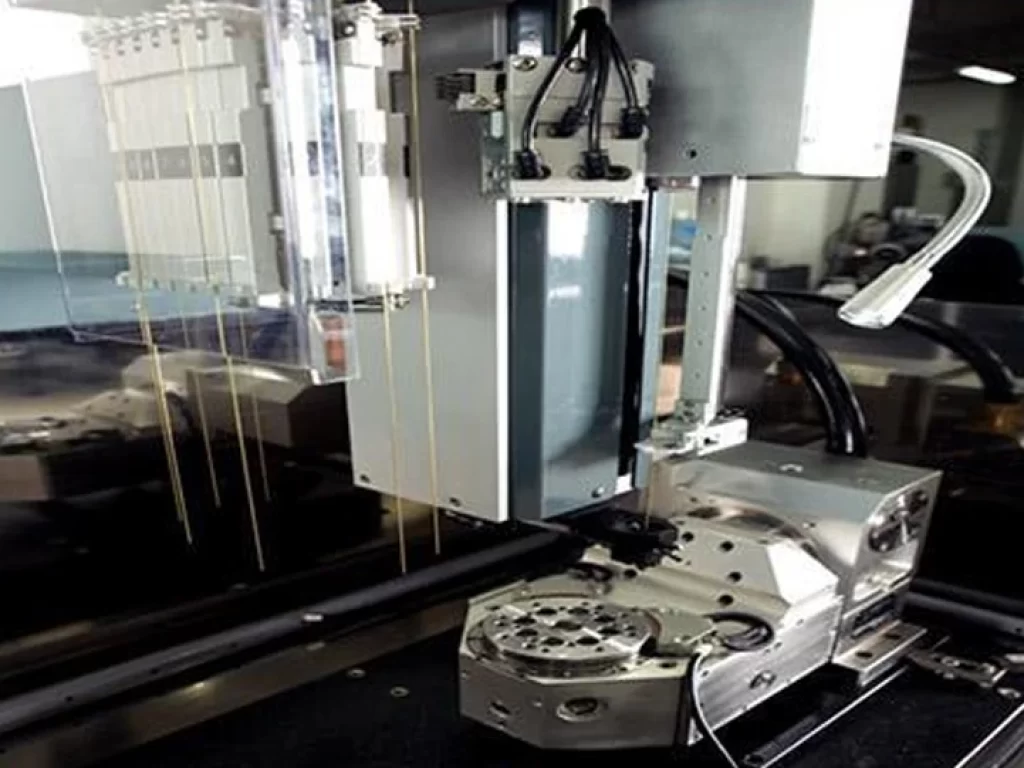

CNC EDM Equipment

EDM Line Cutter Equipment

Horizontal Milling Machine

Rocker Drilling Machine

Universal Rocker Milling Equipment