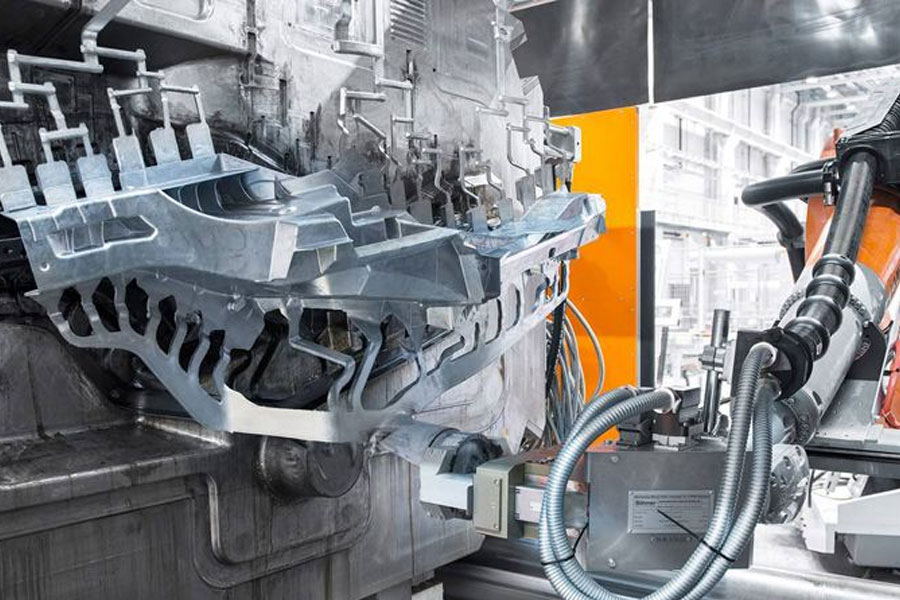

Die-casting mold is one of the three major elements of die-casting production. A die-casting mold with correct and reasonable structure is a prerequisite for the smooth production of die-casting parts, and plays an important role in ensuring the quality of castings (the pass rate of lower machine). Due to the characteristics of the die-casting process, the correct selection of various process parameters is the decisive factor for obtaining high-quality castings, and the mold is the prerequisite for the correct selection and adjustment of various process parameters.

The mold design is essentially the prediction of various factors that may appear in die-casting production. comprehensive reflection. If the mold design is reasonable, there will be fewer problems encountered in actual production, and the casting pass rate will be high. On the contrary, the design of the die-casting mold is unreasonable, such as: the wrapping force of the movable and fixed molds is basically the same when the die-casting parts are designed, and the gating system is mostly in the fixed mold, and it is placed on the die-casting machine where the punch cannot feed after the injection. Die cast parts are stuck to the fixed die all the time.

Although the finish of the fixed mold cavity is very smooth, the phenomenon of sticking to the fixed mold still occurs due to the deep cavity. Therefore, when designing the mold, it is necessary to comprehensively analyze the structure of the casting, be familiar with the operation process of the die-casting machine, understand the possibility of adjusting the die-casting machine and process parameters, master the filling characteristics under different conditions, and consider the processing method of the die-casting mold, Only after drilling and fixing the form can a mold that is practical and meets production requirements be designed. It has been said at the beginning that the filling time of the molten metal is extremely short, and the specific pressure and flow rate of the molten metal are very high, which is extremely bad for the working conditions of the die-casting mold, coupled with the impact of the alternating stress of the cold and hot heat. It has a great influence on the service life of the die-casting mold.

The service life of a die-casting mold usually refers to the number of die-casting molds (including die-casting production) that occur through careful design and manufacture, under normal use conditions, combined with good maintenance and natural damage before they can no longer be repaired and scrapped. the number of scraps in).

Analysis and technical design of main failure modes of die-casting molds

In actual production, there are three main forms of failure of die-casting molds:

- Thermal fatigue crack damage failure;

- Fragmentation failure;

- Dissolution failure.

There are many factors that cause the failure of the die-casting mold, including external factors (such as the casting temperature, whether the mold is preheated, the amount of water-based paint sprayed, whether the tonnage of the die-casting machine is matched, the die-casting pressure is too high, the inner gate speed is too fast, The cooling water opening is not synchronized with the die casting production, the type of die casting material and the level of Fe composition, the size and shape of the casting, the size of the wall thickness, the type of coating, etc.). There are also internal factors (such as the metallurgical quality of the material of the die-casting mold itself, the forging process of the blank, the rationality of the structural design of the die-casting mold, the rationality of the design of the gating system, the internal stress generated during the machining of the mold machine (electrical machining), and the heat treatment of the die-casting mold. process, including various matching accuracy and finish requirements, etc.). If the die-casting mold fails at an early stage, it is necessary to find out what internal or external causes are in order to improve it in the future.

- Thermal fatigue cracking failure of die-casting molds During die-casting production, the die-casting molds are repeatedly subjected to the action of chilling and heating, the molding surface and its interior are deformed, and they are involved in each other, resulting in repeated cycles of thermal stress, resulting in damage to the structure and loss of toughness. , causing the appearance of micro-cracks and continuing to expand. Once the cracks expand, molten metal is squeezed in, and repeated mechanical stress accelerates the expansion of the cracks. To this end, on the one hand, the mold must be sufficiently preheated at the beginning of the die casting. In addition, the die-casting mold must be kept within a certain working temperature range during the die-casting production process to avoid early cracking failure. At the same time, it is necessary to ensure that there are no problems with the internal causes of the die-casting mold before it is put into production and during manufacturing. In actual production, most die-casting mold failures are thermal fatigue crack failures.

- Fragmentation failure Under the action of the injection force, the die-casting mold will crack at the weakest point, especially the scribe marks or electrical machining marks on the molding surface of the die-casting mold are not polished, or the clear corners of the molding are formed. Microcracks will appear first, and when there is a brittle phase at the grain boundary or the grains are coarse, it is easy to break. However, the crack spreads rapidly during brittle fracture, which is a very dangerous factor for the chipping failure of the die-casting mold. For this reason, on the one hand, all scratches and electrical machining marks on the mold surface must be polished, even if it is in the gating system part, it must be polished. In addition, the die-casting mold materials used are required to have high strength, good plasticity, good impact toughness and fracture toughness.

- Melting failure As mentioned earlier, commonly used die-casting alloys include zinc alloy, aluminum alloy, magnesium alloy and copper alloy, as well as pure aluminum die-casting. Zn, Al, and Mg are more active metal elements, which are related to die-casting mold materials. Better affinity, especially Al bite mold. When the hardness of the die-casting mold is high, the corrosion resistance is better, and if there are soft spots on the molding surface, the corrosion resistance is not good. However, in actual production, the corrosion is only a local part of the die-casting mold. In the example, the parts (core, cavity) that are directly eroded by the gate are prone to corrosion, and the aluminum alloy is prone to sticking to the mold where the hardness is soft

Problems often existing in die-casting molds in die-casting production Note:

Pouring system, overflow system

(1) Requirements for the mold sprue on the cold chamber horizontal die casting machine:

- The size of the inner diameter of the pressure chamber should be selected according to the required specific pressure and the degree of fullness of the pressure chamber. At the same time, the deviation of the inner diameter of the sprue sleeve should be appropriately enlarged by a few wires compared with the deviation of the inner diameter of the pressure chamber, so as to avoid the difference between the sprue sleeve and the pressure chamber. Indoor diameters are not coaxial, causing the punch to be stuck or worn out, and the wall thickness of the sprue sleeve should not be too thin. The length of the sprue sleeve should generally be less than the delivery lead of the injection punch, so that the paint can come out of the pressure chamber.

- The inner hole of the pressure chamber and gate sleeve should be finely ground after heat treatment, and then ground along the axis direction, and the surface roughness should be ≤Ra0.2μm.

- The shunt and the cavity forming the coating, the concave depth is equal to the depth of the runner, its diameter matches the inner diameter of the sprue sleeve, and has a 5° slope along the demolding direction. When the coating introduction type sprue is used, the fullness of the pressure chamber can be improved because the volume of the effective length of the pressure chamber is shortened.

(2) Requirements for the runner of the die-casting mold

- The entrance of the runner of the cold horizontal mold should generally be located at more than 2/3 of the inner diameter of the upper part of the pressure chamber, so as to prevent the molten metal in the pressure chamber from entering the runner prematurely under the action of gravity and starting to solidify in advance.

- The cross-sectional area of the runner should gradually decrease from the sprue to the inner gate. If the cross-section is enlarged, negative pressure will appear when the molten metal flows through, and it is easy to inhale the gas on the parting surface and increase the flow of the molten metal. The vortex in the air is wrapped in air. Generally, the section at the outlet is 10-30% smaller than that at the inlet.

- The runner should have a certain length and depth. The purpose of maintaining a certain length is to stabilize the flow and guide. If the depth is not enough, the molten metal will cool down quickly, and if the depth is too deep, the condensation will be too slow, which will not only affect the productivity but also increase the amount of return material. Mold expert WeChat: mujudaren

- The cross-sectional area of the runner should be larger than the cross-sectional area of the inner gate to ensure the speed of the molten metal entering the mold. The cross-sectional area of the main runner should be larger than that of each branch runner.

- Both sides of the bottom of the runner should be rounded to avoid early cracks, and the two sides can be inclined at about 5°. The surface roughness of the runner part is less than or equal to Ra0.4μm

(3) Inner gate

- The parting surface should not be closed immediately after the molten metal enters the mold, and the overflow groove and the exhaust groove should not impact the core directly. After the molten metal is poured into the mold, the flow direction is as far as possible along the cast ribs and heat sinks, filling from the thick wall to the thin wall.

- When selecting the position of the inner gate, make the molten metal flow as short as possible. When using multi-strand inner gates, it is necessary to prevent several strands of molten metal from converging and impacting each other after molding, resulting in defects such as eddy current slug and oxidation inclusions.

- The thickness of the inner gate of the thin-walled part should be appropriately smaller to ensure the necessary filling speed. The setting of the inner gate should be easy to remove, and the casting body should not be damaged (eat meat).

(4) Overflow tank

①The overflow groove should be easily removed from the casting, and try not to damage the casting body.

②When setting up an exhaust slot on the overflow slot, pay attention to the position of the overflow port to avoid blocking the exhaust slot prematurely and making the exhaust slot ineffective.

③Several overflow ports or a very wide and thick overflow port should not be opened on the same overflow tank to prevent the cold liquid, slag, gas, paint, etc. in the molten metal from returning to the cavity from the overflow tank , causing casting defects.

Casting fillets (including corners

The drawings of die-casting parts often indicate requirements such as unmarked rounded corners R2. We must not ignore the role of these unmarked rounded corners when opening the die-casting mold, and must not make clear corners or too small rounded corners. The casting fillet can make the molten metal fill smoothly, discharge the gas in the cavity sequentially, reduce stress concentration, and prolong the service life of the die-casting mold. (Die castings are also not prone to cracks or various defects due to poor filling). For example, the standard oil pan mold has more upper cleaning corners. Relatively speaking, the brother oil pan mold is the best at present, and there are more heavy oil pans.

Demoulding slope

Artificial undercuts are strictly prohibited in the demolding direction (often the castings are stuck in the mold when trying out the mold, and when handled in an incorrect way, such as drilling, hard chisels, etc. to make local concave).

Surface roughnes

The molding part and the gating system should be carefully polished according to the requirements, and should be polished along the demoulding direction. Since the metal liquid enters the casting system from the pressure chamber and fills the cavity, the entire process takes only 0.01-0.2 seconds. In order to reduce the resistance of the molten metal flow and minimize the pressure loss, it is necessary to have a high surface finish. At the same time, the heating and erosion conditions of the gating system are poor, and the worse the finish, the more easily damaged the mold is.

Die-casting mold

The hardness of the forming part Aluminum alloy: about HRC46° Copper: about HRC38° When machining, the mold should try to leave a repair allowance, make the upper limit of the size, and avoid welding.Technical requirements for die-casting mold assembly

Requirements for the parallelism between the parting surface of the die-casting mold and the plane of the template;Requirements for the verticality of guide posts, guide sleeves and formwork;

- The plane of the moving and fixed mold inserts on the parting surface is 0.1-0.05mm higher than the moving and fixed mold sleeve;

- The push plate and reset rod are flush with the parting surface, generally the push rod is recessed by 0.1mm or according to user requirements;

- All movable parts on the mold move reliably, and there is no sluggish phenomenon and no pin string movement;

- The positioning of the slider is reliable, the core is pulled out to keep a distance from the casting, and the matching part of the slider and the block is more than 2/3 after the mold is closed;

- The roughness of the runner is smooth and seamless;

- When the mold is closed, the local clearance of the parting surface of the insert is <0.05mm;

- The cooling water channel is unobstructed, and the import and export signs are marked;

- The surface roughness of the molding is Rs=0.04, and there is no slight damage.