Hot Chamber Die Casting

If you want to choose a china die casting supplier, then Pintejin die casting company is your best choice.If you have a project that uses low melting point alloys, Pintejin die casting company may be able to help. Depending on the demands of your application, Pintejin die casting company may use cold chamber die casting in place of the hot chamber casting process.

Please contact our die casting experts to help you select the best process to meet the needs of your die casting project, or request a quote on your hot chamber die casting project today.

Pintejin die casting company is your premier source for die casting and machining since 1995.

Welcome to send your inquiry or custom designs of die casting parts to be made, we’ll send you a free quote within 24 hours in working days and work out a schedule for recording the progress. Hot chamber castings are most commonly produced at our factory.

What Is Hot Chamber Die Casting?

Hot chamber die casting means that the pressure chamber is immersed in the liquid metal in the heat preservation melting crucible, and the injection part is not directly connected to the base, but is installed on the crucible. The advantages of hot chamber die casting are simple production process and high efficiency; low metal consumption and stable process. However, the pressure chamber and the injection punch are immersed in the liquid metal for a long time, which affects the service life. And it is easy to increase the iron content of the alloy.

The injection chamber is communicated with the gate of the die-casting mold through a gooseneck tube. It is suitable for die-casting zinc, lead and other low-melting non-ferrous alloy parts, and can be widely used in industrial sectors such as automobiles, motorcycle parts, instruments, household hardware, and household appliances.

Every die casting component, including the most intricate high-volume production run, benefits from the presence of skillful, knowledgeable casting industry professionals. Our staff of engineers, materials experts, and experienced craftsmen are on call to make sure Pintejin’s customers have total confidence in their source of supply.Pintejin is committed to inspiring complete customer confidence in our ability to supply hot chamber die casting parts to a wide variety of industries, straight from our plant in Donguan, China.

Why Choose Pintejin Hot Chamber Die Casting Services?

- Easy for mass production – Since die casting is made from die casting mold, they can be obtained within specified tolerance and shapes. Little or no machining is required and thousands of identical castings can be produced before additional tooling is required. So it’s quiet easy to put on mass production.

- Dimensional accuracy and stability – Die casting produces parts that are durable and dimensionally stable, while maintaining close tolerances. They are also heat resistant.

- Strength and weight – Die cast parts are stronger than plastic injection moldings having the same dimensions. Thin wall castings are stronger and lighter than those possible with other casting methods. Plus, because die castings do not consist of separate parts welded or fastened together, the strength is that of the alloy rather than the joining process.

The Advantages of Pintejin Hot Chamber Die Cast

- The complex shapes of parts can be obtained and the performance of parts can be improved. Besides, assembly work is reduced.

- Durable and dimensionally stable die casting parts can be obtained with specified shapes, so no machining or less machining is required.

- Die casting parts can have many finishing techniques and surfaces. The process is capable of achieving smooth or textured part surfaces.

- Net shape part configuration is achievable.

- Intricate cast-in detail

- Reduced porosity

- Longer die casting die life due to lower melting points

- Die design efficiencies = waste reduction

- Fast cycle times(approximately 15 cycles a minute)

- The convenience of melting the metal in the casting maching

The Pintejin Case Studies Of Hot Chamber Die Casting

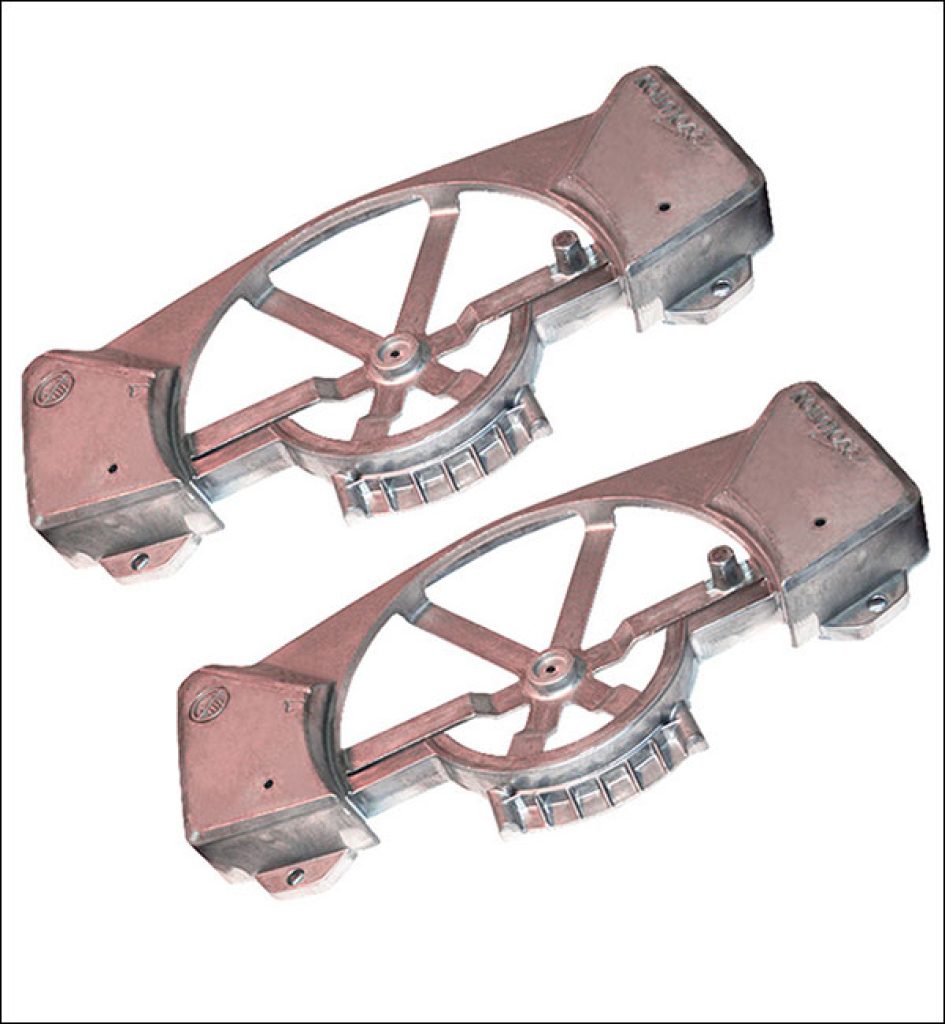

You have a complex part design, Pintejin Die Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Pintejin Die Casting ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

Die Casting LED Display Enclosure

Hot Chamber Die Casting Electronic Parts

Die Casting Motorcycle Battery Box Cover

Hot Chamber Die Casting Automotive Parts

Hot Chamber Die Casting Building Parts

Hot Chamber Die Casting Tubular Parts

Hot Chamber Die Casting Measuring Tool

Hot Chamber Die Casting New Energy Parts

Hot Chamber Die Casting Power Box Housing

Hot Chamber Die Casting Structure Parts

Hot Chamber Die Casting Turbine Parts

Hot Chamber Die Casting Valve Parts