China Top Die Casting Supplier

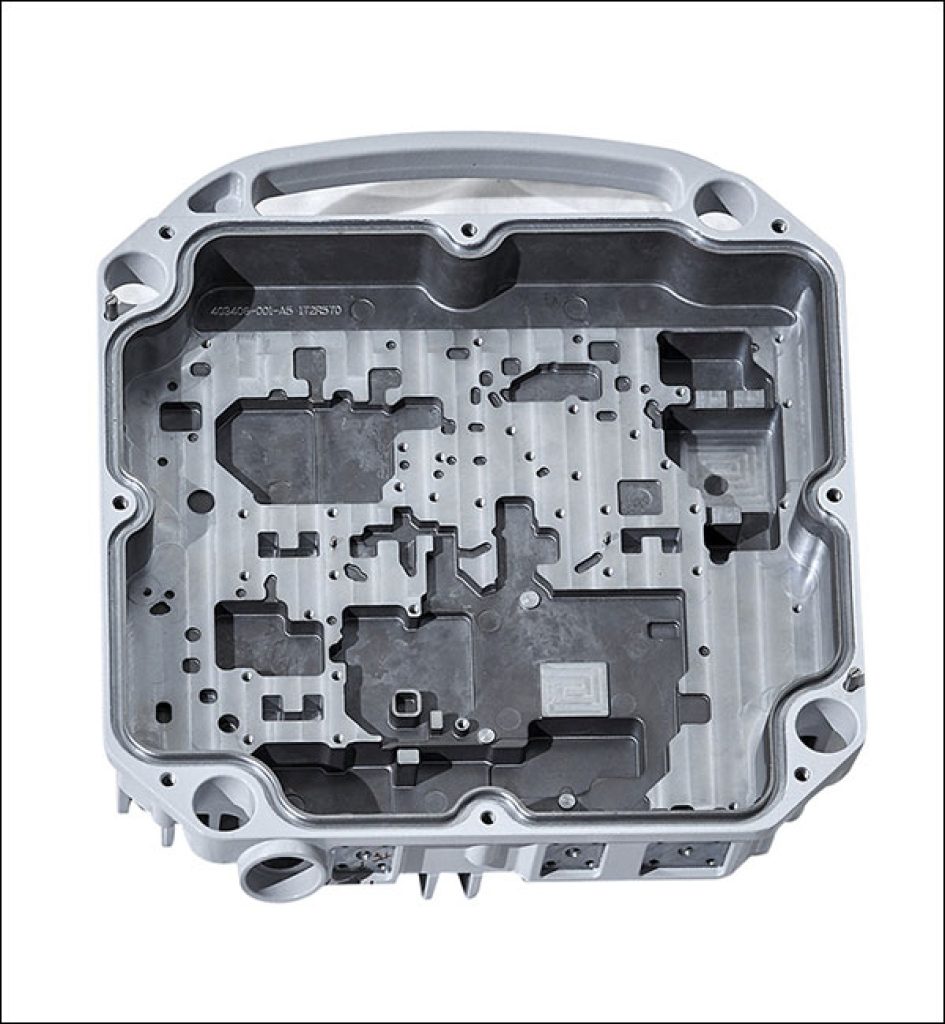

China Metal Die Casting Company specialized in mould design,mould development,aluminum/zinc die casting,fine machining,surface treatment;We provides you a high precision Aluminum Die Casting Parts in ADC 12, A380, A360, 6061, 1070, 2024, 2A12.

Zinc Alloy Die Casting Parts in Zamak 2, Zamak 3, Zamak 5,Zamak 8,CNC Machining, Electroplating, Power Coating, Anodizing & Assembly.

Contact us to know more about our die casting services, which enables us to send you an economical solution for your project in lots of industries.

- Aluminum 360.0, 380.0, ADC`12,etc.,

- Aluminum Alloy Spare Parts

- OEM aluminum die casting parts

- Product size up to 30cm x 30cm

- Machine sizes up to 3000 tons

- Zinc Jewelry,Perfume Bottle,IPC,etc.,

- Zinc Alloy Spare Parts

- OEM zinc die casting parts

- Product size up to 20cmX20cm

- Machine sizes up to 550 tons

- ZEISS CMM

- Pin Gauges

- Roughness machine

- Projector And Micrometer

- Concentricity measurement

- 3 Axis Cnc Machining

- 4 Axis Cnc Machining

- 5 Axis Cnc Machining

- Precision Cnc Turning

- Mill-Turn Machining

DO DIE CASTING SERVICE, WE ARE DIFFERENT

30 Years Of Responsible Service Attitude And Innovate technology, leads to efficient and cost-effective metal die casting solutions

Pintejin Die Casting Company Is A Professional, Reliable Partner for your parts project,We are hornered achieved ISO9001:2015; and ITAF 16949 Certification.Via Improve dimensional accuracy, enhance product surface treatment yield, solve product problems, professional team, professional equipment, reasonable price to ensure that the mold parts are of the highest quality and are cost effective.Pintejin Group Start at 1995 years,focus on many years of precision aluminum die casting, Zamak die casting (Zamak 2, Zamak 3, Zamak 5, Zamak 8) or magnesium die casting and development A developing company!Zinc alloy die-casting, aluminum alloy die-casting, aluminum die-casting, magnesium alloy die-casting, etc. can be guaranteed: can be polished and electroplated, no pitting, no water lines, no blistering, no sand holes, no water seepage, no air leakage, can be Oxidation of various colors, high precision (accurate to +-0.02)…….;With a number of high-quality engineering personnel; With quality service and state of art technology, we indeed claim in providing quality pressure die casting including Hot Chamber Die Castings,Thin Wall Die Casting,Cold Chamber Die Castings and other die casting parts to our customers all over the world.Our expert team of customer care service executives conducts an end-of-project review, measuring ourselves against defined performance criteria and utilizing your feedback to identify the desired changes. Solve all of issue for your products develop requirement until the perfect result.`

Why Choose Our Metal Casting Services?

- Fully automatic production workshop: located in Humen Town, Dongguan City, an independent industrial plant

- Surface Finish Services:Color Rlectrophoresis,Pad Printing, Polishing Rubber, Coating Sand Blasting ,Silk Screen Printing etc.,

- Main operating projects: automatic aluminum alloy die-casting, 5 magnesium alloy die-casting production lines, 80 new CNC machining centers, 10 CNC lathes

- Mold design and development, mold development and development equipment: 10 sets, 5 fully automatic aluminum and zinc alloy processing die-casting production machines, polishing, post-processing workshop

- The company currently has: design and development department, business department, quality control department, production department, etc., which can provide customers with solutions with guaranteed delivery, guaranteed quality and more comprehensive services!

- Has all kinds of main precision die casting processing equipment: independent mold room (spark machine, computer gong, milling machine, precision grinder), precision casting/die casting workshop (30T zinc die casting machine, 128 ton die casting machine, 280 ton die casting machine, 550 ton die casting machine) , 200-ton die-casting machine, 650-ton, 1650-ton die-casting machine, 3,000-ton die-casting machine) polishing room, vibration grinder, sandblasting room, sandblasting room, wire drawing machine, batch front line, full inspection area for shipments, etc.;

Welcome to send your inquiry or custom designs of metai die casting parts to be made, we’ll send you a free quote within 24 hours in working days and work out a schedule for recording the progress. Aluminum die casting parts and zinc die casting parts are most commonly produced at our factory.

Metal Die Casting Equipment Gallery

Pintejin metal die casting company can produce components in Aluminium die casting, Magnesium die casting & Zinc die casting up to 300 tons in Aluminium( Magnesium ) & 100 tons in Zinc per month depending upon the size of the component. We have die casting machines ranging from 30 tons to 3000 tons,Facilities for die casting of rotors for FHP Motors, machining, anodizing & Powder Coating of rotors, riveting of stacks, CNC machining of end-shields also exist.

30T Zinc Hot Chamber Die Casting Machine

200 T Hot Chamber Die Casting Machine

3000T LIBI DIE CASTING MACHINE

Cold Chamber Die Casting Machine Workshop

lijing 280T die casting machine

SANJI Overhaul 550t Die Casting Machine

YIZUMI DM 400t Die Casting Machine

YIZUMI DM 1650t Die Casting Machine

Cnc Machining Equipment Gallery

In-house tool room cnc machining facility to make & maintain precision Die Castings & molds, and have 100% control of a medium-sized machining plant.

4 Axis Mazak Turn-Mill

DMU50 5-Axis CNC

SY-650 Engraving-Mill

Quality Inspection Equipment Gallery

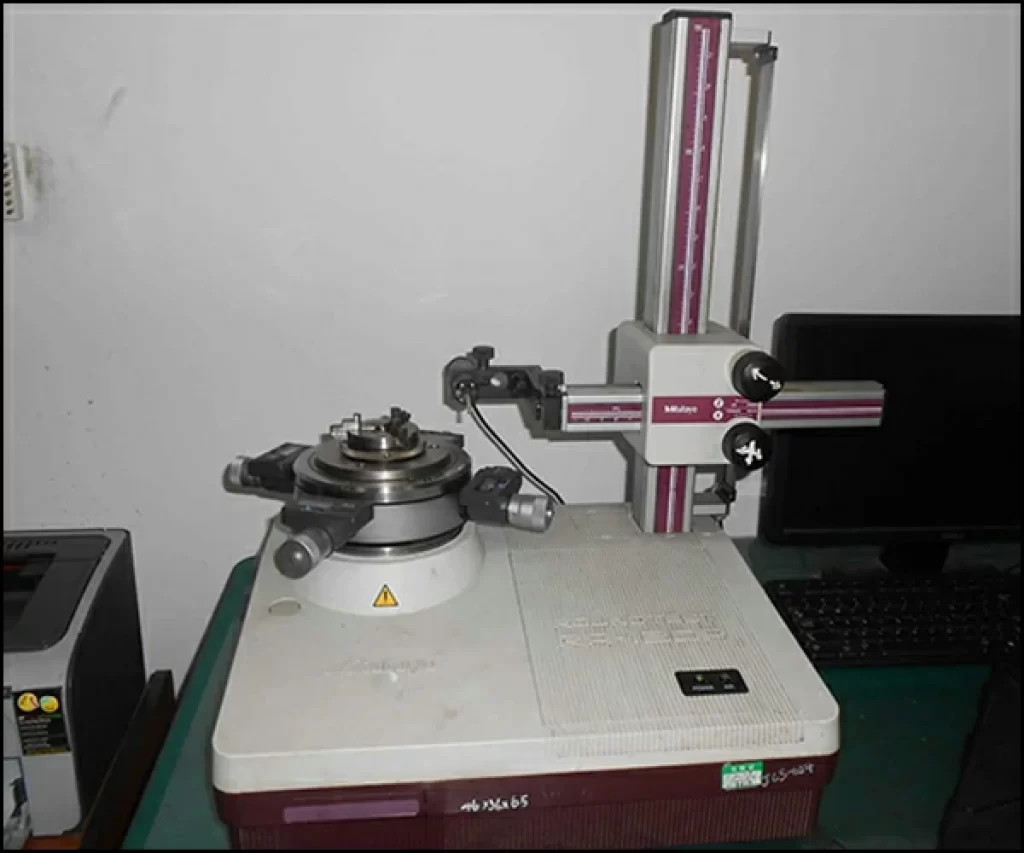

Now we have Zeiss three-coordinate instruments, Mitutoyo roundness measuring instruments, direct reading spectrometers, and are equipped with upright metallographic microscopes and inverted metallographic microscopes.

Zeiss CMM Machine

Mitutoyo Roundness Instrument

Upright metallographic microscope

Looking For Metal Die Casting Services

Make Your Work Less Hassle,Need Not To Look Further Because Pintejin Die Casting Company Is Here To Help

Die Casting is metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are non-iron, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting method, you need to use a cold chamber die casting or a hot chamber die casting.Pintejin Is ISO 9001: 2015 certified manufacturer of die cast aluminum、zinc and magnesium, Turnkey service offered for all aspects of die casting from tooling design、testing to die casting, CNC machining, finishing and export,Capabilities include die casting up to 30 ton hot chamber & 3000 ton cold chamber, mold design, polishing, molding, machining, powder & liquid painting, full QA with CMM capabilities, assembly, packaging & delivery.Pintejin Will provide You Best Die Casting Services,the following is our specific die casting process:

-

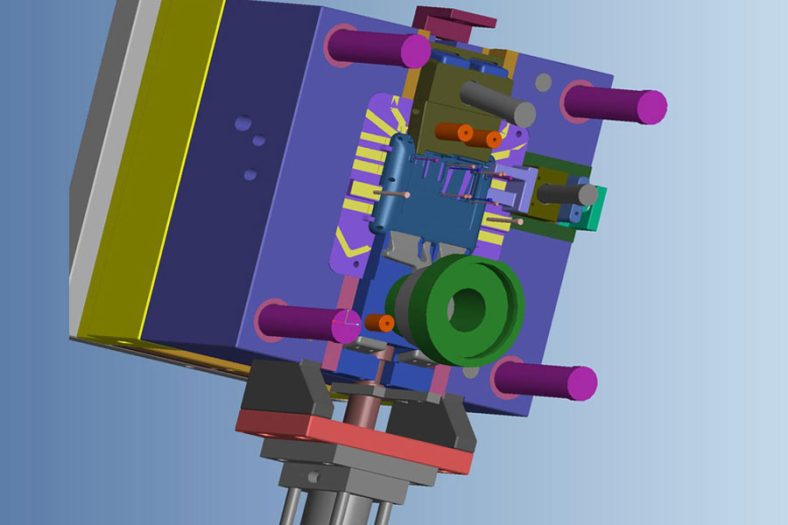

Mold Manufacturing

Die-casting mold is a tool for completing the die-casting process on a dedicated die-casting die forging machine. Pintejin is one of the best mold makers in China, offering mold manufacturing solutions for every industry, including led lighting, cooker, automotive die casting and more.

-

Cold Chamber Die Casting

Cold chamber die casting refers to a die-casting method in which the injection chamber and the injection punch are not immersed in the molten metal, but a quantitative amount of molten metal is poured into the injection chamber, and then injected.

-

Hot Chamber Die Casting

Hot chamber die casting means that the pressure chamber is immersed in the liquid metal in the heat preservation melting crucible, and the injection part is not directly connected to the base, but is installed on the crucible.We offers both medium and long-run projects.

-

Thin Wall Die Casting

The Thin-walled castings of aluminum alloys with characteristic of light-weighting and good mechanical properties have good prospect in producing large complex structure such as vehicle body and automotive chassis. We provide industry-leading thin wall die casting service

Aluminum Die Casting Electronic Parts

Aluminum Die Casting Fish Shaped Bowl

Aluminum Die Casting Street Light Housing

Comb Shape Die Casting Parts

Die Casting Automobile Axle Connecting Parts

Die Casting For Lighting Heat Sink

High Power Downlight Shell By Die Casting

Industrial Computer Power Box Shell

IPC Aluminum Die Casting Enclosure

Magnesium Alloy Die Casting Motorcycle Parts

Zinc#8 Die Casting Electronic Housing

Aluminum Die Casting Massager Parts