Mold Manufacturing

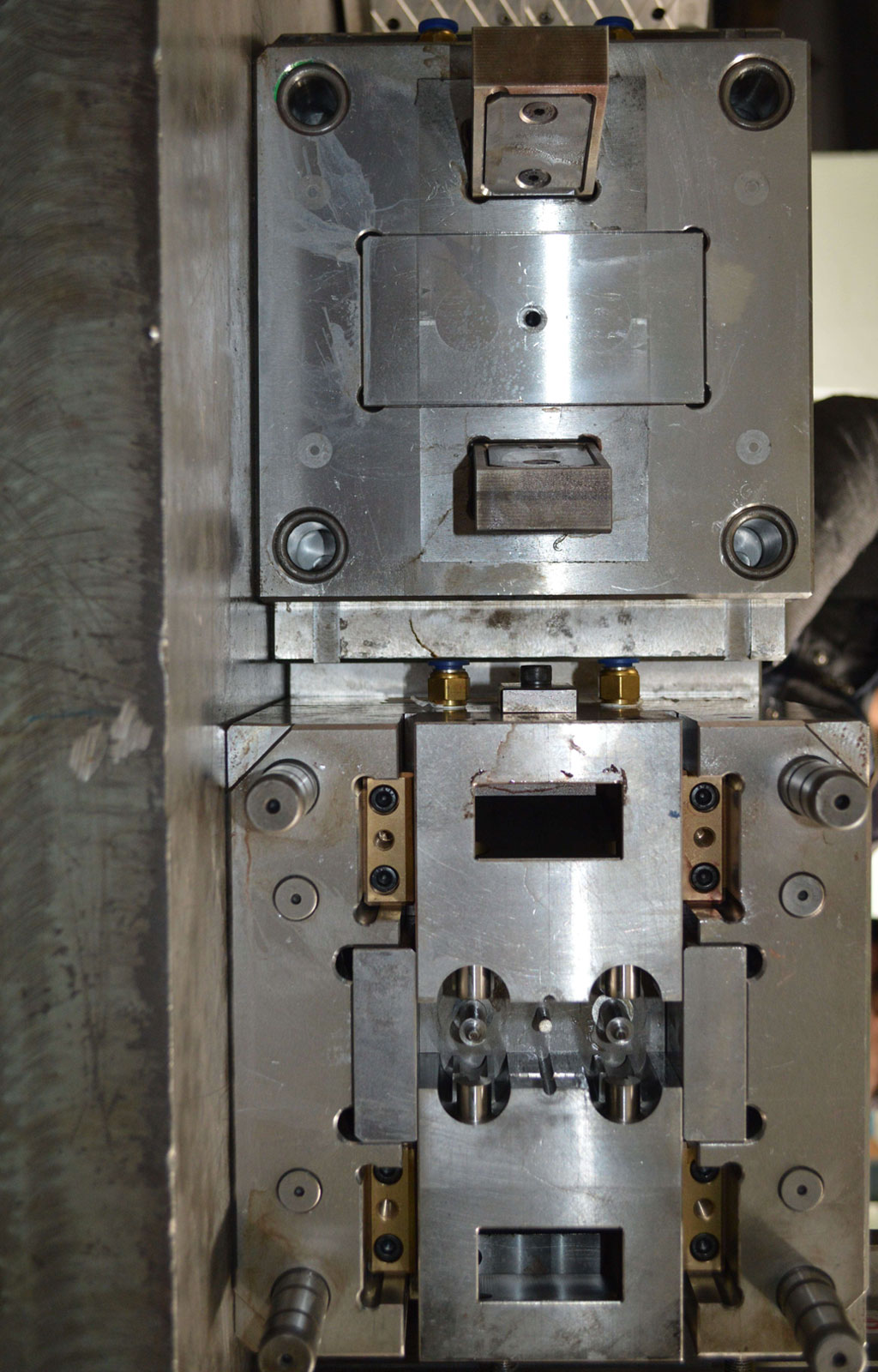

Our mold making room is fully equipped to manufacture custom die casting molds and machined steel parts in-house, 90% of our die casting molds are exported to European and north America, we are familiar with HASCO and DME standard after many years’ focus on export market. Averagely we can supply 25 sets of fully equipped mould making room of china injection mold factorymolds per month, lead time is around 25-35 days depends on the complexity of mold structure, mould bases supplies by LKM, mold steel and heat treatment with certificates apply to customers’ specification, maximum machining capacity 7.5ton, minimum precision 0.005mm.

Pintejin die casting company is your premier source for die casting molds making since 1995.

Tooling & Mold Making Service Online – Best Die Casting Mold Manufacturer In China

Pintejin die casting company is one of the best mold makers in China, offering mold manufacturing solutions for every industry, including led lighting, cooker, automotive die casting and more. Our main services offering include thin wall or more die casting mold manufacturing, die casting & investment casting,sand casting, as well as with CNC machining. With more than 35 years of experience, we are able to produce custom affordable aluminum die casting parts,zinc die casting parts and magnesium parts according to customers’ specifications, drawings or samples. We own advanced techniques, highly skilled staff that employ superior tooling and high pressure die cast processes to ensure that the mold parts are of the cheapest price and highest quality. Whether you need rapid tooling, mass production mold making with tight tolerances, our team of experienced specialists can offer a cost-effective solution at each stage. Contact our expert team and get a price for your tooling/mold making service, we will quote you a die casting and mold manufacturing price in 24 hours!

Why Choose Our Die Cast Mold Manufacturing Services?

There are huge numbers of mold making companies. Why should you choose us as your tooling & die casting supplier? Here are the reasons:

- High production capability and competitive prices for die casting service are offered.

- We have rich die cast mold manufacturing experiences for over 35 years and earned a good reputation.

- Exceptional customer service and communication.

- Multiple of die casting mold designs & types – thin wall, Gravity Casting,Investment casting& sand casting are available to meet custom needs.

- Do precision die casting parts manufacturing according to your drawings or samples.

- Finish the parts with service of mold making in time to provide the strongest support for your R&D projects.

- Our automated quoting, design analysis, and manufacturing process allows us to ship injection molding orders in as fast as 1 day.

- We have advanced production equipment and facility, technology and materials to make the most precise die casting mold as well as great aspect .

- We have the most experienced engineers and tooling partners that will really make a difference in your lead times, costs and final quality.

How To Make Die Casting Mold

There are many factors to consider for Die Casting, but part design for the Die Casting Mold is critical. Getting it right could mean lower entry cost, high production quality, shorter cycle time, and quick assembly. As a source of experienced engineers and product designers, we have an individual or a team of professionals who can help you develop die casting molded parts from scratch. Our team of die casting mold design engineers specialize in drawing with CAD, CAE, CAM, commonly using SOLIDWORKS, PRO ENGINEER, UNIGRAPHICS, and MOLD FLOW analysis software.

What Is Die Casting Mold Manufacturing?

Die-casting materials, die-casting machines, and molds are the three major elements of die-casting production, and none of them are indispensable. The so-called die-casting process is the organic and comprehensive use of these three elements, so that it can stably, rhythmically and efficiently produce qualified castings with good appearance, internal quality, and dimensions that meet the requirements of the drawing or agreement, or even high-quality castings. ;

Die-casting mold is a tool for casting metal parts, a tool for completing the die-casting process on a dedicated die-casting die forging machine. The basic process of die-casting is: first low-speed or high-speed casting of molten metal into the cavity of the mold, the mold has a movable cavity surface, it is pressurized forging with the cooling process of the molten metal, which eliminates the shrinkage of the blank. Loose defects also make the internal structure of the blank reach broken grains in the forged state. The comprehensive mechanical properties of the blank have been significantly improved.

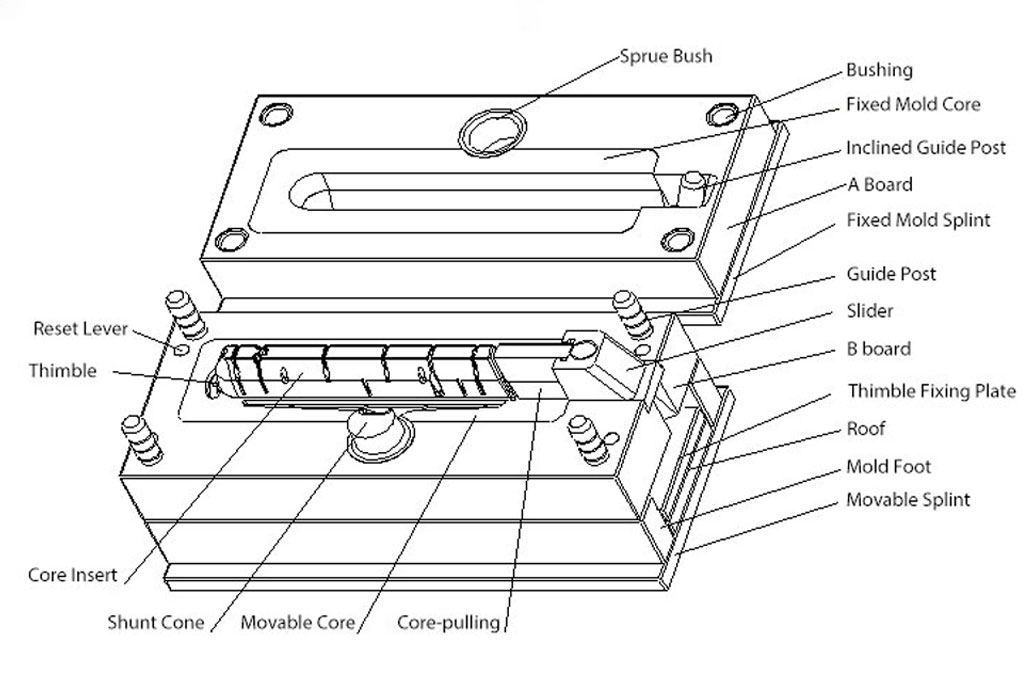

The Composition Of Die Casting Mold

- Molding part (moving and fixed mold core, molding insert, core pulling core, etc.)

- Mould base part (moving and fixed mould splint, AB board, pallet, mould foot)

- Bypass system (sprue sleeve, shunt cone, cross runner, inlet and outlet)

- Overflow system (overflow tank, exhaust tank)

- Ejection mechanism (thimble, thimble fixing plate, ejection plate, reset lever)

- Guide parts (guide post, guide sleeve, middle guide post, middle guide sleeve)

- Core-pulling mechanism (core-pulling slider, oblique guide post, clamping block, spring, etc.)

- Others (cooling system, heating system, strengthening column, etc.)

Common Die Casting Mold Manufacturing Materials

H13 (heat-resistant steel) for front and rear mold cores, core pulling cores, sprue sleeves, shunt cones, etc.); 45# steel (for A, B plates, sliders, inclined guide pillars, etc.); T8, T10 (guide pillars) , Guide sleeve, thimble, reset rod, etc.); A3 steel (front and rear mold splints, pallets, thimble plates, mold feet, etc.)

The parts manufactured by mold making service are used for building and construction, food and beverage, windows and doors, automotive, household appliance, electronics, communications and more industries, car molding, cooker parts, and led lighting parts would be a key part.Whether you only need the product design drawings、Mold Manufacturing or final die casting part with exact specifications, Pintejin Die Casting Company can satisfy your needs with competitive prices, outstanding efficiency and best customer services.